Introduction:

As winter descends, the challenges for forklift operators multiply, and a proactive approach to weather protection becomes crucial. Trinton Castetter, an expert from Toyota Forklift Trucks, shares valuable insights to help operators, supervisors, and facility managers prepare for the harsh winter conditions ahead. This guide explores forklift weather protection across various facets of operations.

Forklift Weather Protection in Facilities:

Operating outdoors in winter requires strategic planning. Identify potential hazards such as icy ramps and pathways. Assess the impact of freezing rain or snow on product safety and visibility. Decision-making in such conditions is pivotal. Operating a forklift in dangerous weather should be strictly avoided, and speed must align with weather conditions.

Forklift Weather Protection for Employees:

Ensuring the safety of all associates is paramount. Operators and pedestrians should dress appropriately for the weather with extra layers and coverage for extremities. Operators must communicate their needs, including gloves, coats, socks, boots, and ear muffs. High visibility clothing becomes essential in adverse weather for enhanced visibility. Safety vests can be invaluable. Regular meetings to evaluate weather conditions and reinforce pre-operation checks contribute to a comprehensive forklift weather protection plan.

Forklift Weather Protection for Forklifts:

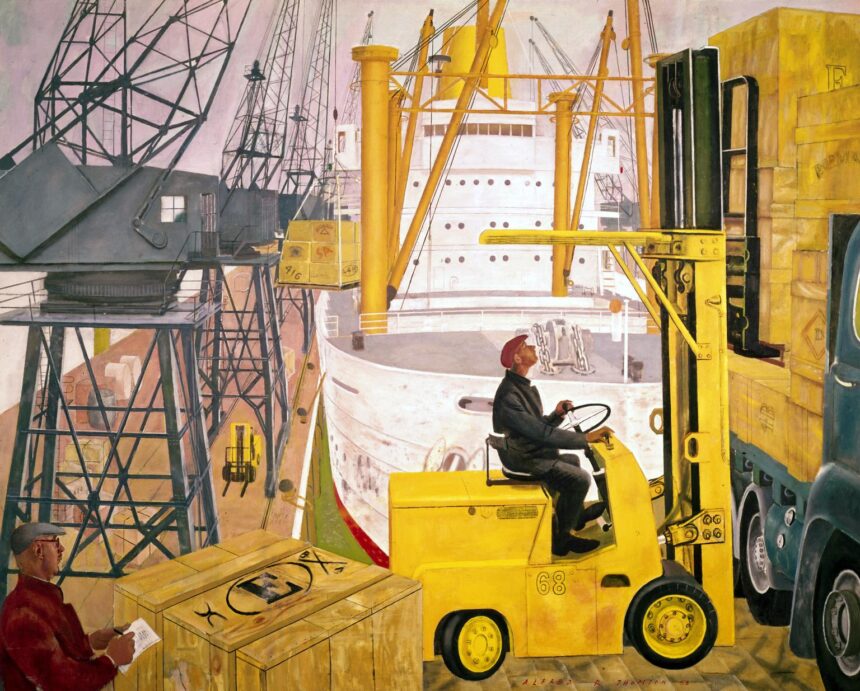

Equipping forklifts with enclosed operator compartments, heaters, and defrosters is crucial for outdoor operations. These features enhance operator comfort and productivity. Cold start aids like engine block heaters and coolant preheaters ensure smooth starts. Specialized batteries designed for cold conditions are vital, considering their impact on forklift functionality. Regular preventative maintenance, especially before winter, and proper battery care contribute significantly to forklift reliability.

Maintaining Productivity in Cold Conditions:

Cold weather adversely affects battery life and run time, necessitating proactive measures. Scheduling preventative maintenance, checking fluid levels, tire conditions, and employing proper battery care are essential. Regular maintenance should be a year-round commitment. For electric forklifts, managing water levels and limiting exposure to cold weather are critical practices. Planning battery charging options and having an ample supply of batteries minimize downtime risks.

HSE Guidance and Temperature Considerations:

The Health and Safety Executive (HSE) offers valuable advice on workplace temperatures. Accessing their guidance ensures compliance with safety regulations and provides additional insights into managing cold conditions.

Conclusion:

Preparing for winter conditions involves a holistic approach encompassing facilities, employees, and forklifts. Trinton Castetter’s comprehensive guide emphasizes the importance of strategic planning, regular maintenance, and proactive measures to ensure safety and productivity during the challenging winter months. By adopting these practices, the forklift industry can navigate winter challenges with resilience and efficiency.

Leave a Reply